Waste-to-Energy Plants

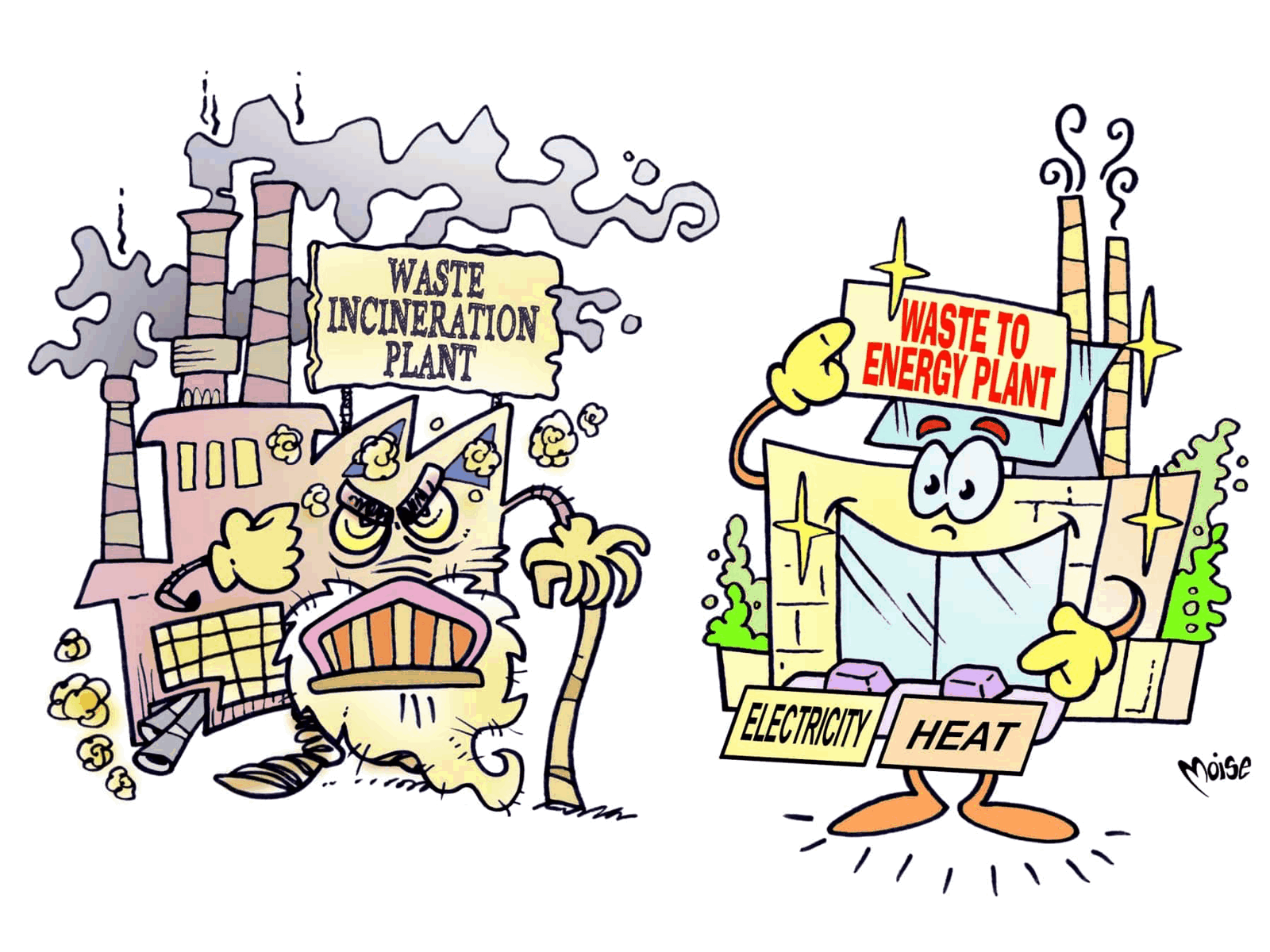

The possibility of recovering energy from waste material represents a demarcation line between the new waste-to-energy plants and the old incinerators. But that’s not the only difference!

Technological evolution allows the new plants to function with minimum environmental impact. Waste-to-energy plants are subject to severe laws on the emission of gases

(the fumes are treated to cut down the amount of polluting agents before being released into the atmosphere) and to periodic controls to verify their compliance with specific parametric values.

As already mentioned, for some parameters, such as carbon monoxide and nitric oxide levels, the emissions are lower than those produced by fossil fuels.

Only waste which cannot enter the recycling “circuit” is treated in the waste-to-energy plants (such as residual urban waste, sludge, hospital waste and non-hazardous industrial waste).

In some plants, the waste, before entering the combustion chamber, undergoes a pre-treatment process in order to separate the dry waste from the wet waste and to “hold back” the metals that can be recovered.

Waste combustion takes place at a temperature of about 1000°C; the heat created is used to produce electricity and can be exploited to produce thermal energy to be sent into a district heating network,

replacing private boilers in the homes served. Most of the residual waste is recovered: today only 3-4% of waste treated is not transformed into electricity, heat or recoverable material

(mostly metals sent to the foundries and ash, that can be reused, after special treatment, for building purposes).

The possibility of recovering energy from waste material represents a demarcation line between the new waste-to-energy plants and the old incinerators. But that’s not the only difference!

Technological evolution allows the new plants to function with minimum environmental impact. Waste-to-energy plants are subject to severe laws on the emission of gases

(the fumes are treated to cut down the amount of polluting agents before being released into the atmosphere) and to periodic controls to verify their compliance with specific parametric values.

As already mentioned, for some parameters, such as carbon monoxide and nitric oxide levels, the emissions are lower than those produced by fossil fuels.

Only waste which cannot enter the recycling “circuit” is treated in the waste-to-energy plants (such as residual urban waste, sludge, hospital waste and non-hazardous industrial waste).

In some plants, the waste, before entering the combustion chamber, undergoes a pre-treatment process in order to separate the dry waste from the wet waste and to “hold back” the metals that can be recovered.

Waste combustion takes place at a temperature of about 1000°C; the heat created is used to produce electricity and can be exploited to produce thermal energy to be sent into a district heating network,

replacing private boilers in the homes served. Most of the residual waste is recovered: today only 3-4% of waste treated is not transformed into electricity, heat or recoverable material

(mostly metals sent to the foundries and ash, that can be reused, after special treatment, for building purposes).